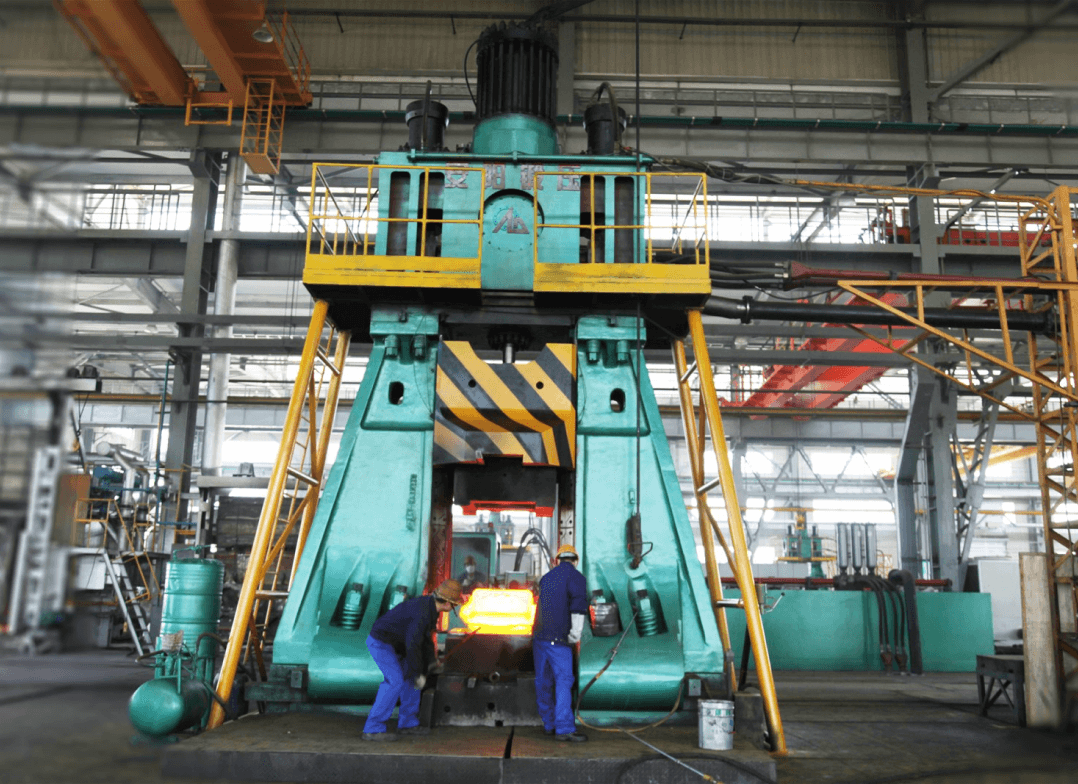

Forging Department

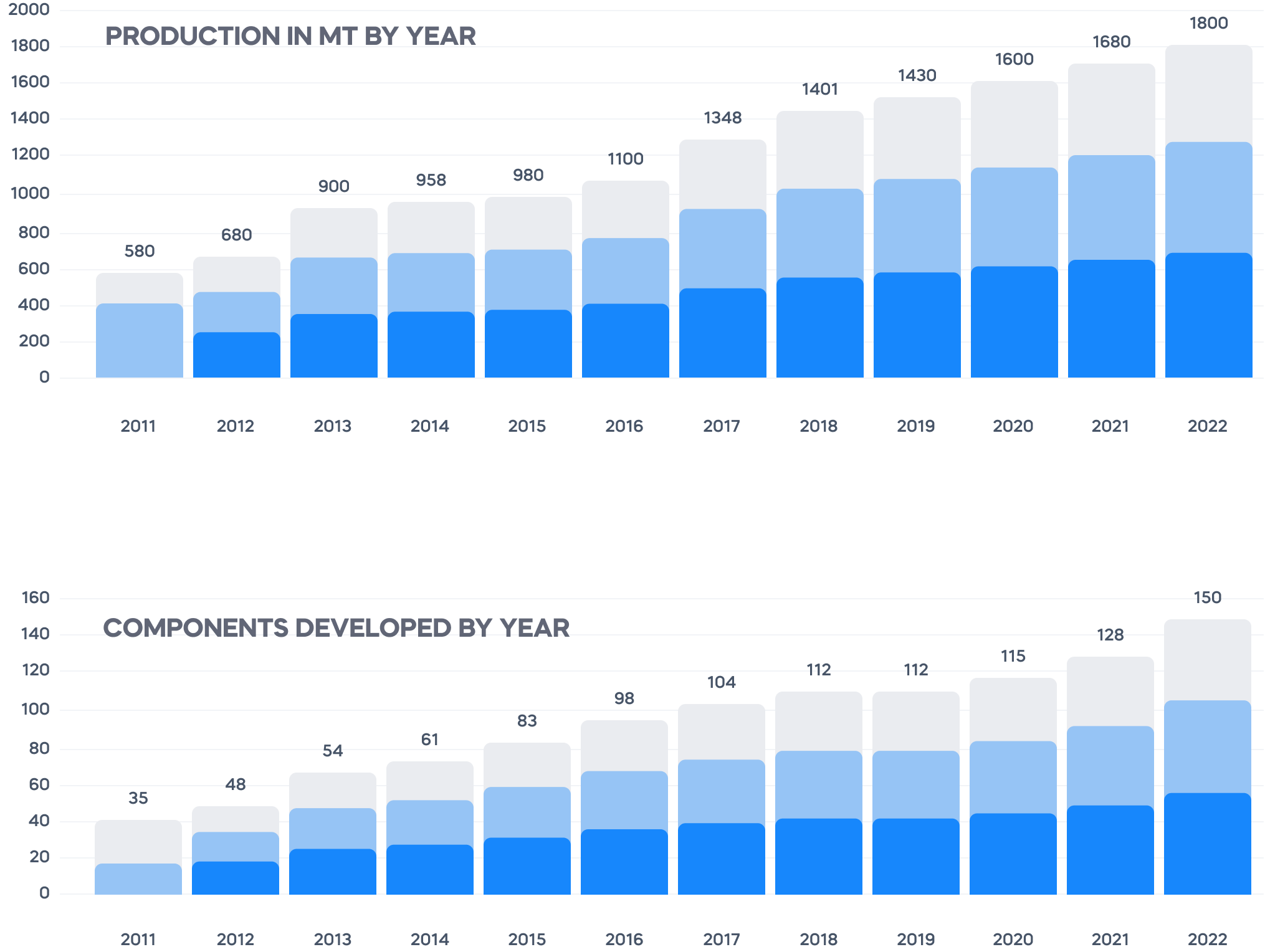

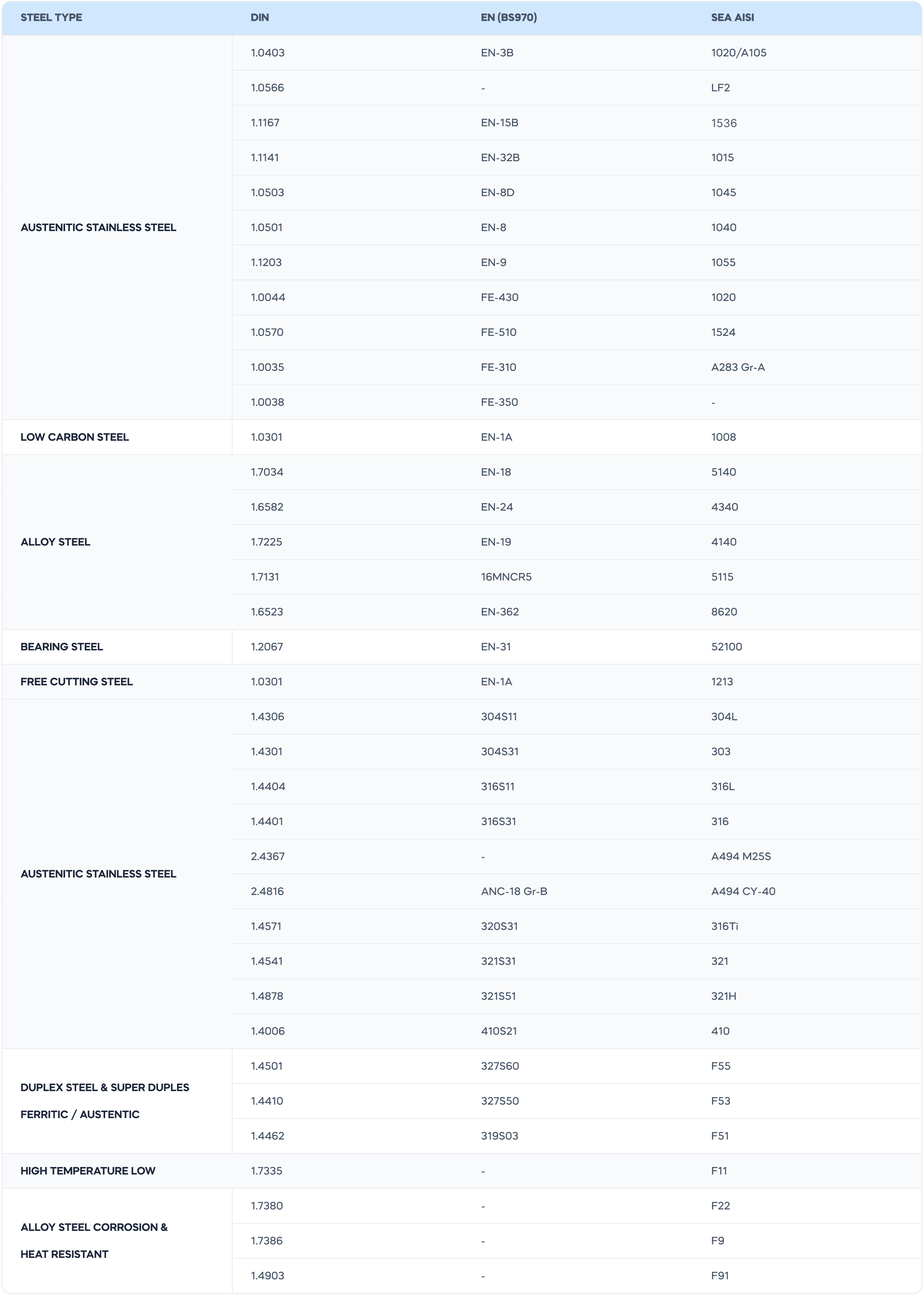

We produce our forging 0.250 Kilograms t o 35 Kilograms/component. from wide verity of material, which suites customer specification and standard for many industries.

We produce our forging 0.250 Kilograms t o 35 Kilograms/component. from wide verity of material, which suites customer specification and standard for many industries.

Forged and machined products are inspected visually and dimensionally, with third-party checks if needed, to ensure customer requirements are met before dispatch.

We have an in-house CNC shop with 6 CNC centers, 8 lathes, and 4 copping machines, plus outsourced CNC turning and milling services.

Company has in house Normalizing & ISO Thermal Annealing Facility with continuous d a t a logger & Alarm System.

The cutting department ensures precise material sizing for efficient forging, using advanced machinery to optimize accuracy and reduce waste.

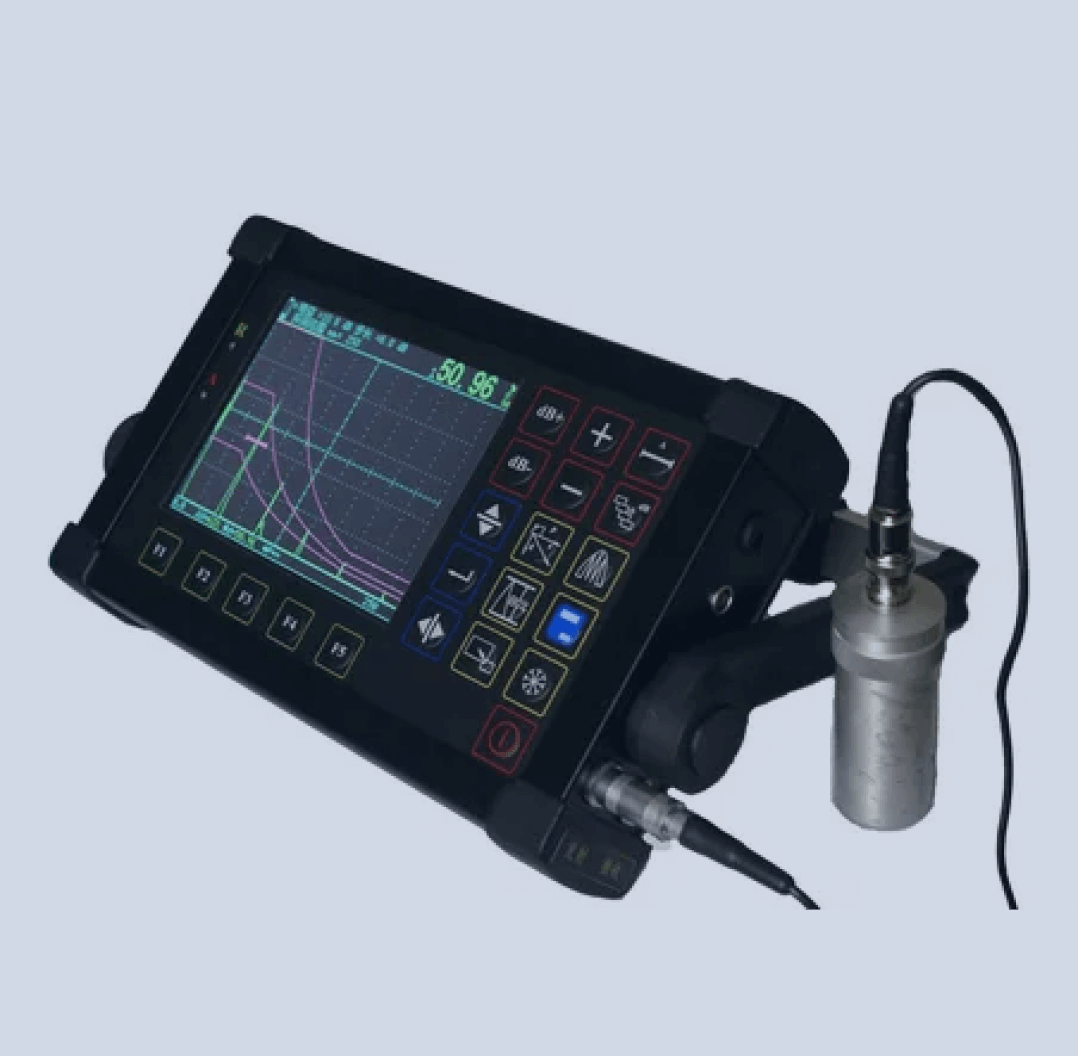

Our In-house Metallurgical Lab is equipped with advanced tools and technologies to ensure the highest quality of forged components.

STF Committed To Achieve Customer Satisfaction Through Manufacture And Timely Supply Of Qualityproduct As Per-International Standards And Continual Improvement Of Quality Management System.

We supply the products into Auto Parts Ring, Oil & Gas & Engine Parts, Submersible Ring, and Metal Gasket Ring. We already developed Diff. types of Ring. Our manufacturing product weightvaries from 0.5 kg. To 25 kg. And 360 mm in dia. (Ring Rolling)

Rudra Technoforge was registered as a company in the year 2009 to supply excellent quality forged products to our customers. We achieved the ISO Certification in the year 2013 and has recently been awarded ISO/TS 16949:2009 in the year of 2016.

Whether you need custom-designed forgings or precision-machined components, we are here to help you achieve your project goals.